Austenitic stainless steel

Austenitic stainless steel is one of the most common types of stainless steel, with good corrosion resistance and plasticity. Its main components are 18% to 20% chromium and 8% to 10% nickel, and usually contains a small amount of molybdenum, manganese, and other elements. Common representatives include 304 and 316 stainless steel:

1.304 stainless steel

- Features: commonly used austenitic stainless steel, with good corrosion resistance and plasticity.

- Applications: kitchen utensils, household appliances, chemical equipment, etc.

2.316 stainless steel

- Features: Contains more nickel and molybdenum, has stronger corrosion resistance and high-temperature resistance.

- Applications: marine environment, medical equipment, seawater treatment, etc.

Ferritic stainless steel

Stainless steel is composed primarily of ferrite, with a higher chromium content (typically 11% to 27%) and a lower nickel content, which makes ferritic stainless steels slightly inferior to austenitic stainless steels in terms of corrosion resistance, but has high strength and good heat resistance. Common ferritic stainless steels are 430 and 409 stainless steel:

1.430 stainless steel

- Features: Commonly used ferritic stainless steel with good corrosion resistance and strength.

- Applications: kitchen utensils, household appliances, automobile exhaust pipes, etc.

2.409 stainless steel

- Features: High chromium content, suitable for high temperature and chemical corrosion environment.

- Applications: auto parts, petrochemical, architectural decoration, etc.

Martensitic stainless steel

Martensitic stainless steel contains higher carbon content (about 0.1%-1.2%) and can obtain higher hardness and strength through heat treatment. Relatively speaking, martensitic stainless steel has poorer corrosion resistance. Typical representatives are 410 stainless steel, 420 stainless steel, and 440C stainless steel:

1. 410 stainless steel

- Features: High hardness and strength, medium corrosion resistance, and plasticity.

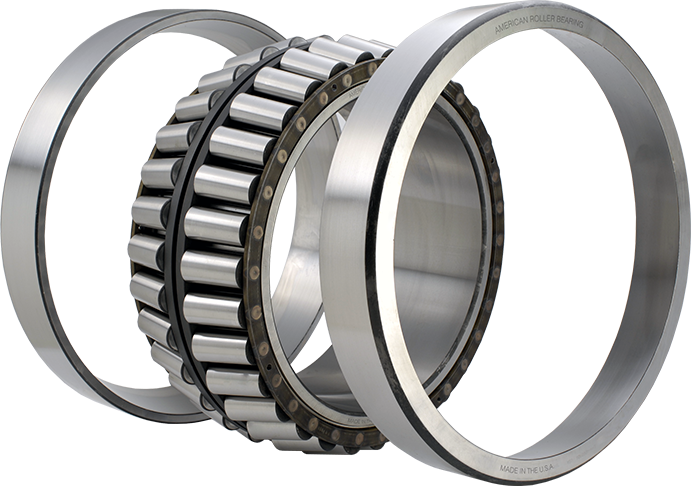

- Application: Commonly used to make blades, saw blades, screwdriver bits, bearing parts and valves, etc.

2. 420 stainless steel

- Features: The carbon content is slightly higher than 410 stainless steel, with higher hardness and strength, good wear resistance, and corrosion resistance.

- Application: Commonly used to make knives, medical equipment, bearings, valves, auto parts, etc.

Duplex stainless steel

Duplex stainless steels are a unique type of stainless steel consisting of an austenite and a ferrite phase. It is characterized by combining the advantages of both austenitic and ferritic stainless steels, including excellent strength and corrosion resistance. Common representatives of duplex stainless steel are 2205 and 2507 stainless steel:

1.2205 stainless steel

- Features: Contains both austenite and ferrite phases, with excellent strength and corrosion resistance.

- Applications: chemical equipment, offshore oil and gas production, etc.

2.2507 stainless steel

- Features: Higher nickel and molybdenum content, higher corrosion resistance and strength.

- Applications: Pipelines and valves in offshore engineering, oil and gas industries, etc.

In addition to the above main classifications, there are some other special types of stainless steel, such as titanium alloy stainless steel, high hardness stainless steel, etc. Different types of stainless steel have different properties, and each stainless steel has unique advantages in specific fields. Understanding the types of these stainless steels and their applicable scenarios will help us make wise choices when choosing stainless steel materials.

Stainless steel has become an indispensable precious material to promote industrial development and create a better life. If you have stainless steel needs, please feel free to contact us. AnGang is a world-renowned stainless steel manufacturer and will provide you with the most professional advice. The most suitable product and the best service!