Product specifications

|

Customized support

|

OEM, ODM

|

|

Place of Origin

|

China

|

|

Brand Name

|

AnGang |

|

Material

|

Stainless Steel |

|

Size

|

customizable |

|

Standard

|

ANSI JIS DIN ASME

|

|

MOQ

|

1 ton

|

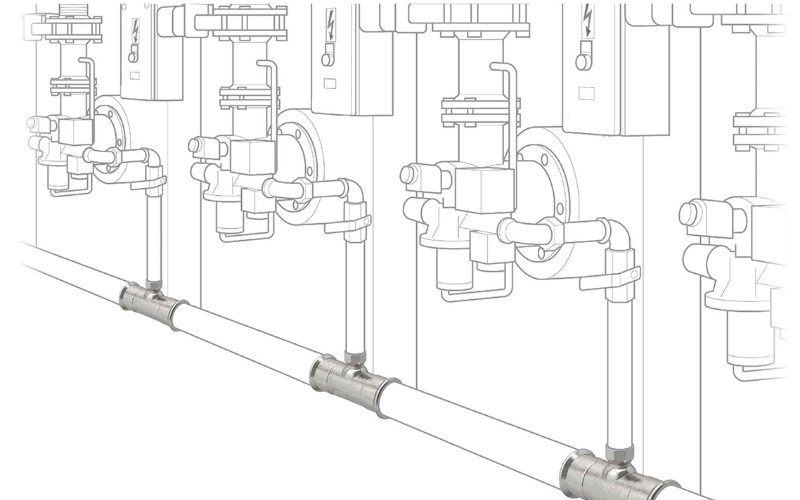

Application of stainless steel pipe fittings

Stainless steel pipe fittings are widely used because of their excellent corrosion resistance and high-temperature resistance in every industry.

Applications in the automotive industry: The high-temperature resistance, corrosion resistance, and high-pressure performance of stainless steel pipe fittings make them suitable for automobile exhaust systems, fuel systems, cooling systems, etc., which can meet the different needs of automobiles, improve the performance and service life of automobiles, and reduce the pollution caused by emissions of gases to the environment.

Application in the food processing industry: Stainless steel pipe fittings are often used in the food processing industry to connect processing equipment, storage tanks and filling machines, and other equipment, which can ensure the safety and hygiene of food raw materials and finished products in the transportation process.

Application in the natural gas industry: Stainless steel pipe fittings are commonly used in the natural gas industry to support and connect natural gas pipelines, and are used to connect various components in the pipeline to ensure the connectivity and flow direction of the pipeline. Stainless steel pipe fittings are also used in natural gas detection and control systems, such as presses, regulating valves, and other equipment, to detect and regulate the flow and pressure of natural gas.

Application in the chemical industry: Stain steel pipe fittings are widely used in the chemical industry for storage tanks, reactor inlet, and outlet pipes, connecting pipes, and various auxiliary equipment to meet the chemical industry’s control requirements for chemical substance transportation and discharge. Stainless steel pipe fittings are also used to connect the inlet and outlet pipes of centrifuges and filtration equipment so that materials can be efficiently carried out during the flow and separation process.

Application in the Marine industry: stainless steel fittings are common joint fittings on ships, which can ensure the circulation and heat dissipation of cooling media, and ensure the safe transportation and storage of fuel. In the ship’s fire fighting system, stainless steel pipe fittings are also very important, to ensure the delivery and spraying of water, stainless steel pipe fittings are usually used as a link between the fire fighting system pipe and the nozzle.

What are the materials of stainless steel pipe fittings?

Implementation standards:

ASTM:ASTM A403, ASTM A8158, ASTM A270, etc

IOS: IOS 2852, IOS 2037, IOS 5251, etc

EN: EN 10253, EN 10312, etc

GB: GB/T 19228 etc

Material:

Austenitic stainless steel: 304 (18-8 stainless steel), 304L, 316, 316L, etc

Ferritic stainless steel: 430, 439, etc

Martensitic stainless steel: 410, 420, etc

Duplex stainless steel: 2205, 2507, etc

There are some special materials of stainless steel, such as high alloy stainless steel, high-temperature stainless steel, etc., the chemical composition and performance of different materials are also different, and the appropriate stainless steel material can be selected according to the application environment.

How are stainless steel pipe fittings produced?

The production process of stainless steel pipe fittings: raw material re-inspection—cutting—high-temperature heating—shaping—welding—heat treatment (some pipe fittings need heat treatment to improve mechanical properties)—groove processing—surface treatment—finished product inspection—painting Marking – packaging and shipping

Stainless steel pipe fittings installation tips

Before installing stainless steel pipe fittings: before installing stainless steel pipe fittings, measure the size and connection position of the pipe fittings, and select the appropriate stainless steel pipe fittings; clean the stainless steel pipe fittings and connected pipes to ensure that the surface is smooth, free of impurities and corrosive substances; select appropriate pipe fittings to ensure The tightness of stainless steel pipe fittings and pipeline connections.

The installation process of stainless steel pipe fittings: choose the appropriate connection method according to the specific application of the pipeline. If you choose welding, you should pay attention to the angle of welding and the magnitude of the current to ensure the welding quality; when choosing threaded connection, pay attention to the tightness of the threaded connection to avoid damage to the pipe fittings due to overtightening.

After the installation of stainless steel pipe fittings: after the installation of stainless steel pipe fittings, pressure testing should be carried out in time to ensure the tightness of the pipeline and avoid accidents such as leakage. Regularly check and clean stainless steel pipe fittings. If there is corrosion, wear, and other phenomena, it should be repaired or replaced in time.

Stainless steel pipe fittings and copper pipe fittings which are good?

Stainless steel pipe fittings and copper pipe fittings are common pipe connection materials, but their performance and application fields are also different:

Corrosion resistance: Stainless steel pipe fittings have excellent corrosion resistance and can resist acid, alkali, and other corrosive agents; copper pipe fittings have poor corrosion resistance and will be affected by various corrosive substances.

Strength and hardness: stainless steel pipe fittings have high strength and hardness, and can withstand high pressure; copper is a softer material, and pipe fittings made of copper have lower strength and hardness.

Thermal conductivity: Copper is a high-quality thermal conductivity material, suitable for applications or occasions that require high thermal conductivity, while stainless steel has poor thermal conductivity.

Cost: The price of copper is higher than that of stainless steel, and the cost of copper pipe fittings is higher than that of stainless steel pipe fittings.

Application: Stainless steel pipe fittings are suitable for industries requiring high corrosion resistance, such as petrochemical, petroleum, food processing, etc. Copper pipe fittings are used in civil fields such as water supply and heating.

Why does everyone choose stainless steel pipe fittings?

Corrosion resistance: Stainless steel pipe fittings have excellent corrosion resistance and can resist the erosion of various chemical substances. They are suitable for chemical, petroleum and other industries. Their corrosion resistance reduces the cost of maintenance and replacement.

Sanitation: Stainless steel is a non-toxic and harmless material that will not release harmful substances to cause any harm to the human body, and meets hygiene and food safety standards.

Easy to clean: The stainless steel surface is smooth and not easy to accumulate bacteria and dirt.

Machinability: Stainless steel has high machinability and can be designed according to the needs of various shapes and specifications of pipe fittings.

Eco-Friendly: Stainless steel is a recyclable material that reduces your environmental impact.

What are the factors that affect the life of stainless steel pipe fittings?

The influence of pipeline design on the service life of stainless steel pipe fittings: the position of stainless steel pipe fitting design is very important to the service life of stainless steel pipe fittings, and the correct position can prolong the service life of stainless steel pipe fittings. During the installation process, if the stainless steel pipe fittings are too tight or too loose, it will increase the damage of the stainless steel pipe fittings, thereby reducing the service life of the stainless steel pipe fittings.

Effect of wall thickness on service life of stainless steel pipe fittings: The wall thickness of pipe fittings affects the compressive strength of the piping system. If the wall thickness is too thin, the connection strength and corrosion resistance will be reduced, which will affect its service life.

The impact of environmental factors on the service life of stainless steel pipe fittings: long-term exposure of stainless steel pipe fittings to harsh environments such as high temperature, strong acid, and strong alkali will cause wear or corrosion of stainless steel pipe fittings, thereby shortening the service life.

The influence of maintenance on the service life of stainless steel pipe fittings: Regular inspection and maintenance of stainless steel pipe fittings can effectively reduce corrosion, wear and other problems, thereby prolonging the service life of stainless steel pipe fittings.

The influence of working environment on the service life of stainless steel pipe fittings: high temperature and high pressure environment will reduce the mechanical properties of stainless steel pipe fittings, resulting in shortened service life of stainless steel pipe fittings.