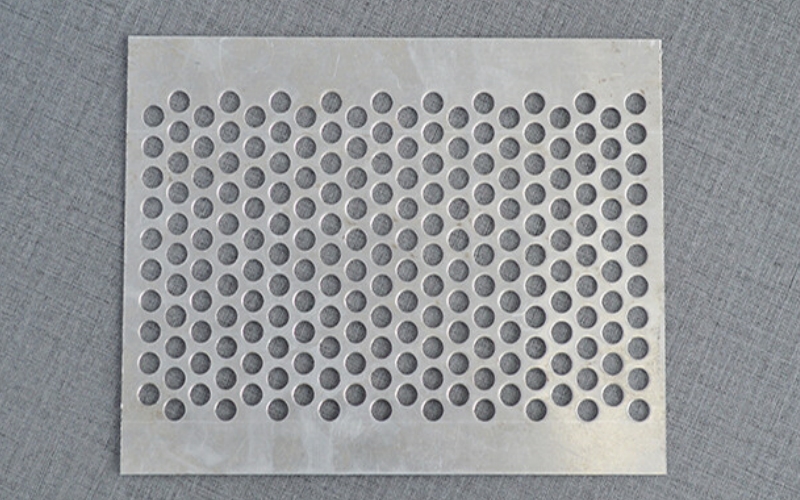

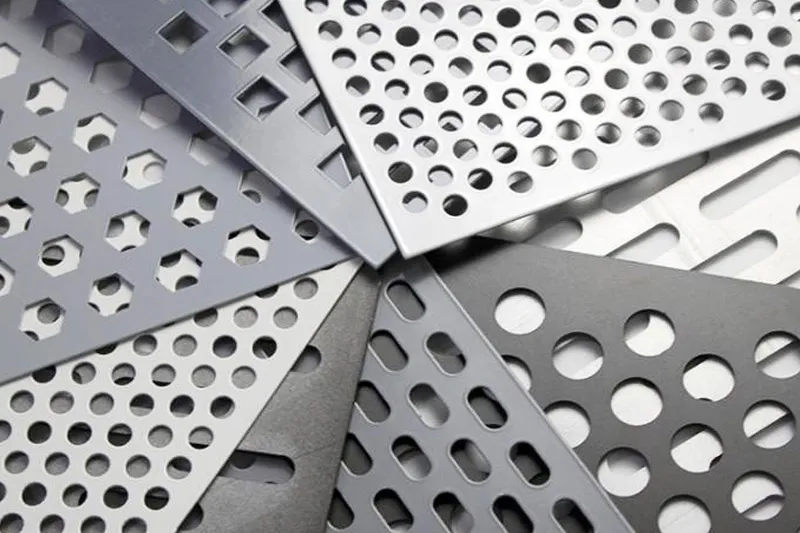

Stainless steel perforated plate, also known as stainless steel round hole plate, is a sheet metal that has been mechanically punched, stamped, or cut on stainless steel plates. This method is ideal to create different hole sizes, shapes, or patterns for practical or aesthetic purposes. Therefore, it is widely in HVAC projects (heating, ventilation, and air conditioning), internal and external cladding, sound suppression, screening, structural support, furniture, and more. AnGang perforated stainless steel plates are available in many different hole shapes, pitches, sizes, and grades. If you are interested, come to contact us for more details!

Perforated Stainless Steel Plate Specifications

| Raw Material | stainless steel plate |

| Standards | JIS, AISI, ASTM, GB, DIN, EN |

| Grades | 304, 310, 316, 321, 409, 410, 420 |

| Thickness | 0.5 – 15 mm or according to the customer’s requirements |

| Width | 600 – 1500 mm or according to the customer’s requirements |

| Length | 800 – 2000 mm or according to the customer’s requirements |

| Hole size | 0.2 -155 mm or according to the customer’s requirements |

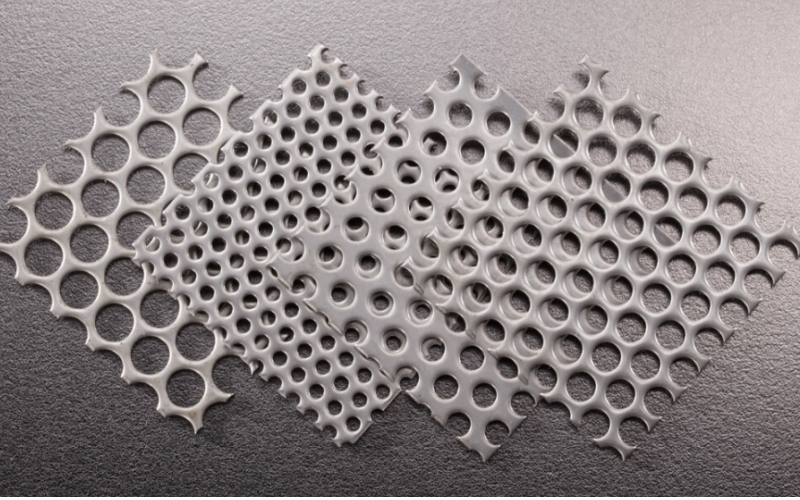

| Hole patterns | round, square, rectangular, slotted or elongated, hexagonal, triangle, geometric, micro-porous, diamond, irregular holes, or according to the customer’s requirements |

| Finish | 2B, 2D, BA, No 4., HL, 6K/8K, brushed, polished, etc |

| Punching arrangement methods | straight row (90 degrees straight ), staggered row (60 degrees staggered or 45 degrees staggered), irregular row, combination arrangement of large and small holes, etc |

| Value-added service | cutting, rolling, folding, welding, bending, etc., |

| Package | plastic film packing and pallet transportation, or according to the customer’s requirements |

Precautions

1. Generally speaking, the hole size of a stainless perforated plate must not be lower than the thickness of a stainless perforated plate, which is the principle of the smallest hole of the perforated plate. For example, if the thickness of the perforated plate is 1.0 mm, then the minimum aperture of the perforated plate can be made 1 mm; if the thickness of the punching plate is 5 mm, then the minimum aperture of the perforated plate can be made 5 mm.

2. When cleaning and maintaining the stainless perforated plate, do not contain strong acid or alkaline substances in the washing. Because these substances will directly form oxidation and rust with other material components in the steel except chromium, thus causing corrosion.

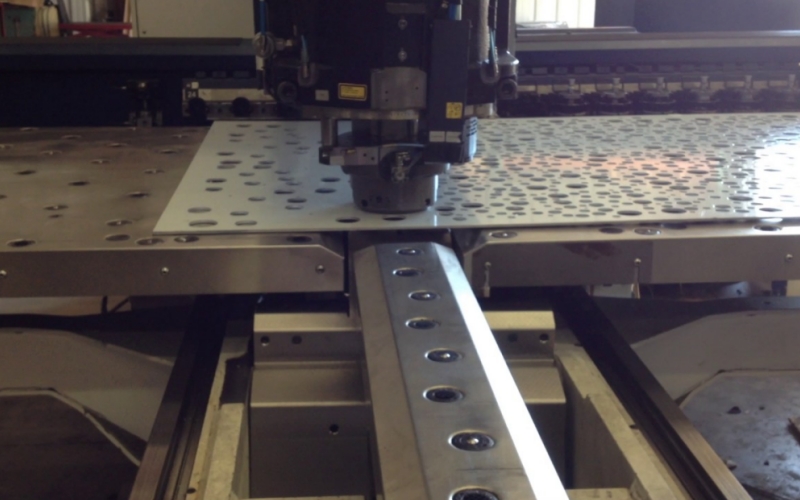

How Is Stainless Perforated Plate Made?

When it comes to perforating, computer numeric controlled (CNC) equipment is commonly used since it can be easily programmed to pass rapidly over a sheet of stainless steel, placing holes with precision and accuracy. Here are some important steps you can have a look at.

1. Material preparation: take out the stainless steel plates.

2. Mold preparation: prepare the hole size and hole patterns that the customer needs.

3. Machine oiling: the punching machines are usually cooled with lubricating oil as the metal-on-metal friction makes them very hot.

4. Punching: fix the stainless steel plate on the punching machine. When operating, the perforating punches continuously move up and down, creating holes in the stainless steel.

5. Plate leveling: Because the punching mesh is subjected to different stress levels during the production process, it may be deformed. We should use a leveling machine to restore the punched and deformed punching plate to its original flat state.

6. Plate cutting: we used to produce a whole stainless steel plate, and after the production is completed, we need to cut it into the standard size required by customers.

7. Plate cleaning: clean and tidy the surface of the plate.

8. Examining: check if the product is qualified.

9. Packing: the finished products will wait for transportation.

Benefits of Stainless Steel Perforated Sheet Plate

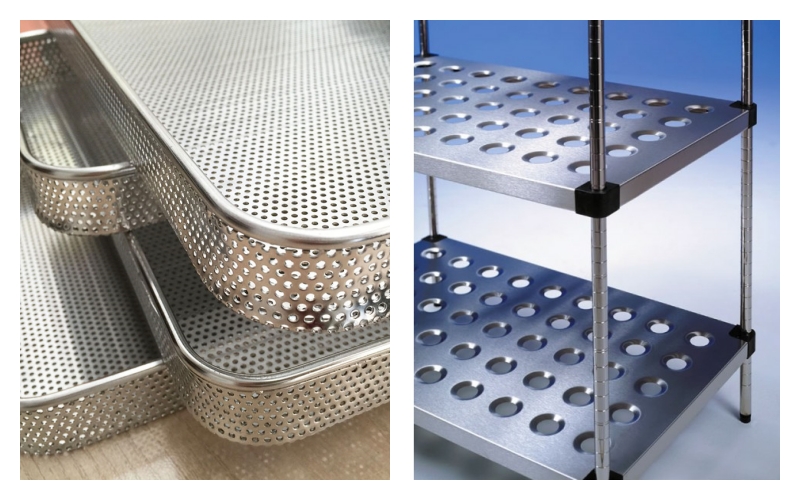

Stainless steel perforated material can be used for a wide range of applications. That’s because this type of product has several interesting benefits for a variety of projects. Here you can have a look.

1. Excellent Corrosion and Rust Resistance

This kind of sheet uses a stainless steel plate as substrate, which is an alloy material containing chromium to resist iron oxide formed by interaction with oxygen. This provides excellent corrosion and rust resistance. Therefore, it can be widely used in various corrosive environments.

2. Flat surface & Light Weight

From the naked eye, the stainless perforated plate offers a pleasant and satisfying appearance. It has flat mesh, uniform holes, silver-white color, lightweight, and simple design, making it ideal for forming into three-dimensional shapes to increase strength and rigidity. Besides, with a wide variety of patterns and thicknesses to choose from, you have some control over the level of sunlight that enters a building.

3. Long Lifespan & Great Durability

It has a long service life, which is 3 to 5 times that of ordinary steel perforated plate. When fabricated into perforated designs, these metals have the same aesthetic appeal as lighter metals but are strong enough to endure harsh and stressful conditions. This particular feature of perforated metals is one of the reasons that they are so widely used.

4. Good Filtration Performance

With its unique hole pattern designs, the perforated stainless steel plate combines functional and decorative performance. It has good air permeability, light permeability, and water permeability, which can reduce the blockage and loss of materials and reduce energy consumption.

5. Sound Absorption Property

Studies have shown that perforated metals help reduce sound levels. Therefore, stainless perforated metal is frequently used for diffusing sound, soundproofing, and reducing acoustic emissions. This performance helps people or workers limit the health effects of noise.

6. High Strength & Good Processability

Despite the holes, perforated metal meshes are still very strong and tough. Accordingly, it can be further processed by cutting, welding, bending, and so on.

7. Easy Maintenance

Its smooth surface is not easy to accumulate impurities, which is conducive to cleaning and maintenance.

8. Environmental-friendly Solution

It is a green material that can satisfy both customers’ and society’s needs.

Firstly, all perforated metals can be reused, gathered, recycled, and formed into new sheets. This reduces the depletion of our natural resources and promotes sustainability.

Secondly, by its very nature, perforated metal is eco-friendly, using less metal than a metal panel of the same size. The perforations decrease the amount of metal between 10% and 40%. The reduced weight means less fuel is required to transport it to your projects.

Finally, it can improve energy efficiency and building performance.

What Are the Applications for SS Perforated Metal Plates?

Perforated stainless steel sheet is suitable for a range of structural and decorative applications, including but not limited to:

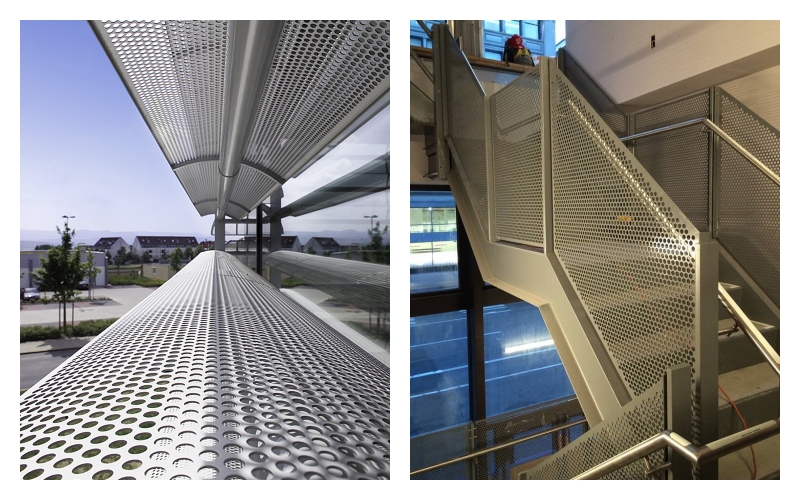

1. Construction

It can be applied in various structural steel works, internal and external cladding, infill panels, suspended ceilings and lighting, facade systems, partitions walls, floors, windows, doors, arcades and awnings, gates, grates, safety coverings, column covers, shop fittings, site amenities, etc.

2. Noise Reduction

It can be applied in noise-reducing equipment, soundproofing sheets, speaker grilles, diffusers, and so on.

3. Fencing & Screening & Filtering

Firstly, it can permit the passage of light, liquid, and air. The applications include air conditioning guards, HVAC projects (heating, ventilation, and air conditioning), filtration parts, water waste projects, etc.

And then, The different hole shapes on the plate provide a screening possibility. The uses can be found in various screens, sorting machines, drying and separating sieves, potato separators, fruit and vegetable juice presses, etc.

Finally, when used for fencing, it can be used for mechanical and animal protection, including grilles, enclosures for cattle, expressway fencing, etc.

4. Transportation

Stainless steel perforated metals are also an ideal material used for the manufacture of automobiles. They have excellent strength but are lightweight enough to fit a vehicle’s needs. It can be found in, radiator grilles, muffler guards, heat shields, automotive repair, trailer parts, stair reads and risers, vessel components, lorries, buses, trains, subway trains, ships, airbag traps, loudspeaker covers and car tuning, and the like.

5. Home Appliances

It can be some essential components for household appliances, including coolers, draining boards, washing machine filters, doors for microwaves, drums for washing machines, centrifugal vessels, grills for kitchen stove vents and range vent hoods, grill racks, supplementary graters for meat-grinding machines, perforated lids for pots and pans and the like.

cable trays, computers, videos, satellite receivers and transmitters, set-top boxes, casings for house service boards, etc.

6. Public Uses

It can also be used in various DIY applications, light fixtures, park benches, trash receptacles, fences, billboards, message and notice boards, furniture decorations, shelf systems, litter baskets, kitchenware, food & beverage processing, pharmaceutical & chemical processing, oil and gas exploration equipment, commercial signs and so on.