Before getting to know the 300 series stainless steel coil, let us first understand what is 300 series stainless steel. 300 series stainless steel is a class of austenitic stainless steel, the main alloying elements include chromium and nickel. It has excellent corrosion resistance and can resist the attack of oxidative, acidic, and alkaline media.

The 300 series stainless steel coil is a thin and long coil product made of 300 series stainless steel. The production process includes multiple processes such as raw material heating treatment, hot rolling or cold rolling process, deviation correction, and shearing. These coils have the advantages of good corrosion resistance, high strength, easy maintenance, and beautiful appearance.

It is widely used in construction, food processing, catering equipment, and other fields, and is used to manufacture storage tanks, pipelines, food processing equipment, and other industrial equipment that require corrosion resistance and high temperature.

Product Specification

Mechanical Properties of 301, 304, 316, And 321 Stainless Steel Coils:

| Mechanical Properties | 301 Stainless Steel Coil | 304 Stainless Steel Coil | 316 Stainless Steel Coil | 321 Stainless Steel Coil |

| Tensile Strength (MPa) | 520-720 | 515-690 | 515-690 | 520-720 |

| Yield Strength (MPa) | ≥205 | ≥205 | ≥205 | ≥205 |

| Elongation (%) | ≥40 | ≥40 | ≥40 | ≥40 |

| Hardness (HB) | ≤207 | ≤187 | ≤187 | ≤187 |

| Impact Energy (J) | – | – | ≥50 | – |

| Rockwell Hardness (HRB) | ≤95 | ≤90 | ≤90 | ≤90 |

| Rockwell Hardness (HRC) | ≤28 | ≤28 | ≤28 | ≤28 |

| Modulus of Elasticity (GPa) | 193 | 193 | 193 | 193 |

| Poisson’s Ratio | 0.27-0.30 | 0.27-0.30 | 0.27-0.30 | 0.27-0.30 |

Chemical Element Composition of 301, 304, 316, And 321 Stainless Steel Coils:

| Chemical Elements | 301 Stainless Steel Coil | 304 Stainless Steel Coil | 316 Stainless Steel Coil | 321 Stainless Steel Coil |

| Carbon (C) | ≤0.15% | ≤0.08% | ≤0.08% | ≤0.08% |

| Silicon (Si) | ≤1.00% | ≤0.75% | ≤0.75% | ≤0.75% |

| Manganese (Mn) | ≤2.00% | ≤2.00% | ≤2.00% | ≤2.00% |

| Phosphorus (P) | ≤0.045% | ≤0.045% | ≤0.045% | ≤0.045% |

| Sulfur (S) | ≤0.030% | ≤0.030% | ≤0.030% | ≤0.030% |

| Chromium (Cr) | 17.0-19.0% | 18.0-20.0% | 16.0-18.0% | 17.0-19.0% |

| Nickel (Ni) | 6.0-8.0% | 8.0-10.5% | 10.0-14.0% | 9.0-12.0% |

| Molybdenum (Mo) | – | – | 2.0-3.0% | – |

| Titanium (Ti) | – | – | – | ≥5×(C+N) ≤0.70% |

The above data are the common specifications of our company’s 300 series stainless steel coils, and the actual chemical element content will vary according to specific order requirements. When selecting and purchasing 300 series stainless steel coils, please feel free to contact us for more detailed information.

What Is the Difference Between 300 Series Stainless Steel Coils?

300 series stainless steel coils are a group of common stainless steel coils, including 301, 304, 316, and 321 models. They differ in chemical composition, mechanical properties, and fields of application. 301 stainless steel is suitable for spring manufacturing and high-strength components, 304 stainless steel is widely used in food processing, chemical equipment, and architectural decoration, 316 stainless steel has good corrosion resistance and is suitable for marine environments and chemical industries, while 321 stainless steel coils are used in high-temperature environments Excellent performance, commonly used in heat treatment equipment and aerospace fields. According to specific needs, choose the appropriate stainless steel coil.

Is 300 Series Stainless Steel Coil Good?

300 series stainless steel coil has become the material of choice in many industries due to its excellent corrosion resistance, excellent mechanical properties, and wide range of applications. The specific advantages are as follows:

- Excellent high-temperature resistance.

- Excellent corrosion resistance can resist the erosion of various chemical substances.

- Excellent plasticity, suitable for various processing and forming processes.

- Good solderability, easy to weld and connect.

- Neat and beautiful appearance, and a good surface finish.

- The mechanical properties of the material can be maintained in a large temperature range.

- A variety of specifications and sizes are available and can be customized.

- Wide range of applications, meeting different application requirements.

How to Tell the Stainless Steel Coil’s Quality?

To identify whether the stainless steel coil is of high quality, it is recommended to analyze it from the following aspects:

- Material standards and certifications: High-quality stainless steel coils comply with international standards and have relevant certification documents.

- Surface Quality: High-quality stainless steel coils have a flat, smooth surface with no visible blemishes or damage.

- Chemical composition: High-quality stainless steel coils have a suitable chemical composition, including appropriate amounts of chromium, nickel, and other alloying elements.

- Mechanical properties: High-quality stainless steel coils have good mechanical properties such as high strength, yield strength, and ductility.

- Corrosion resistance: The high-quality stainless steel coil has been specially treated to have excellent corrosion resistance, which can resist the attack of corrosive media and oxides.

Considering the above factors comprehensively, it is possible to distinguish whether the stainless steel coil is of high quality or not. At the same time, choosing reputable suppliers and producers is also an important factor to ensure the acquisition of high-quality stainless steel coils. As a leading supplier in the country, AnGang has won the trust and satisfaction of customers with excellent service and reliable product quality and promises to provide customers with high-quality 300 series stainless steel coils to meet the needs of various applications.

What Is a 300 Series Stainless Steel Coil Used for?

Due to its excellent corrosion resistance, oxidation resistance, and mechanical properties, 300 series stainless steel coils are widely used in various industries to meet the needs of different fields, including but not limited to the following:

Construction industry: used to manufacture building structures, columns, bridges, handrails, etc.

Chemical industry: suitable for manufacturing storage tanks, pipelines, chemical equipment, reactors, distillation towers, etc., to resist corrosive media and high-temperature environments.

Food processing industry: used in the manufacture of food processing equipment, storage tanks, pipelines, etc. to ensure food safety and hygiene, while having good resistance to corrosive substances in food.

Automobile manufacturing industry: used in the manufacture of automobile exhaust systems, intake pipes, fuel tanks, etc., which can effectively resist high temperature, high pressure, and corrosive environments.

Aerospace field: suitable for manufacturing aero-engine components, turbine blades, spacecraft structures, etc., to cope with extreme working conditions.

Medical Devices: Used in the manufacture of surgical tools, medical equipment, surgical implants, etc. to ensure their corrosion resistance and biocompatibility.

Oil and gas industry: suitable for manufacturing oil storage tanks, pipelines, valves, etc. to withstand high pressure, high temperature, and corrosive media.

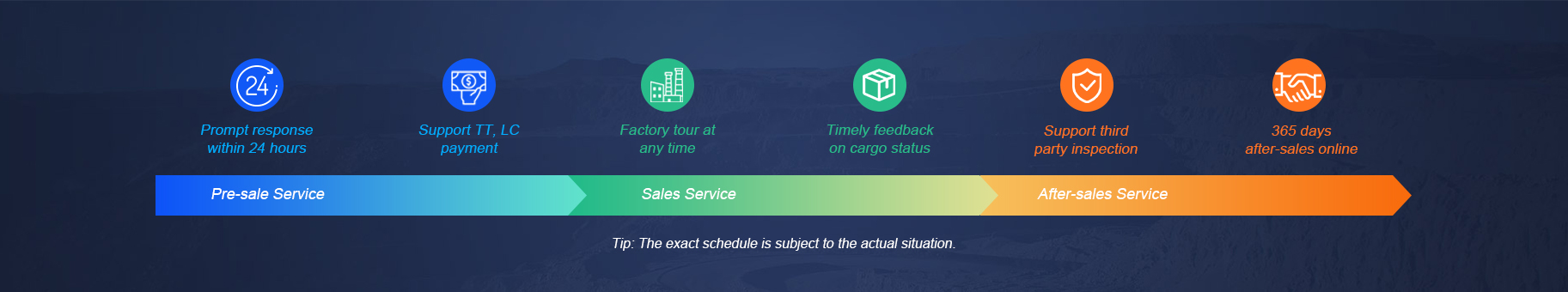

Reasons to choose AnGang

The AnGang Steel Group is a professional supply chain enterprise, mainly engaged in steel plate, coil, profile, and outdoor landscape design and processing. After 15 years of development, it has become a leading international steel supply chain company in the Central Plains. Relying on many iron and steel enterprises such as Angang Steel, we have a wide variety of products, including shipbuilding plates, pressure vessel plates, bridge decks, etc. We also provide pipes, bars, engineering design and manufacturing, and comprehensive stainless steel solution services. Cooperating with more than 600 companies around the world, the annual export capacity exceeds 80,000 metric tons. Choose AnGang Steel Group, you choose a professional and reliable steel supply chain partner!