What Is Type 316 Stainless Steel Coil?

316 stainless steel coil is a high-quality stainless steel product, mainly composed of elements such as chromium, nickel, and molybdenum. Exhibits excellent corrosion resistance, especially suitable for resisting corrosion in acidic and saline environments. At the same time, it also has high strength and high-temperature resistance and can be widely used in chemical, marine, medical equipment, food processing, and other fields.

316 Stainless Steel Coil Specification

| Type | 316 Stainless Steel Coil |

| Standard | AISI, ASTM, JIS, SUS, GB |

| Chemical Composition | includes elements such as carbon, silicon, manganese, phosphorus, sulfur, chromium, nickel, molybdenum, and iron, among which the content of chromium, nickel, and molybdenum is relatively high. |

| Finish (surface) | 2B, BA, HL, No. 4, mirror surface, etc. |

| Thickness(mm) | 0.3-3 (cold rolling) /3-18 (hot rolling) |

| Width(mm) | 600-2000 / customized |

| Strength (MPa) | 500-700 |

| Elongation | 40%-50% |

| Elongation | 4040 |

| Hardness (HB) | 150-220 |

| Elastic modulus (GPa) | 190-210 |

The specifications and dimensions in the above table are only common options, and the specifications and dimensions of the actual product can be customized according to your needs.

Why Choose 316 Stainless Steel Coil?

316 stainless steel coil is a commonly used stainless steel material with many excellent properties, making it a leader in stainless steel coil products and widely used in many fields. The specific reasons for choosing it are as follows:

Good Corrosion Resistance

The chemical composition of 316 stainless steel coil contains about 2-3% molybdenum, which has stronger corrosion resistance. It is resistant to the corrosion of chemical substances such as sulfuric acid, acetic acid, and alkaline chloride, and is suitable for corrosive environments such as marine environments and chlorine-containing media.

High-temperature Performance

It has a high high-temperature resistance performance, can still maintain structural stability and strength in high-temperature environments, and is not easy to oxidize or thermal expand. It is suitable for high-temperature equipment and heating elements.

Excellent Mechanical Properties

Good strength and plasticity make it easy to process and shape during the manufacturing process, with high tensile strength, yield strength, and impact resistance and can withstand large forces and pressures.

Excellent Welding Performance

316 stainless steel coil has excellent welding performance, and can be connected and assembled by various common welding methods. The welded joint has good strength and corrosion resistance, which can meet complex manufacturing needs.

Hygienic Performance

316 stainless steel coil is a non-toxic, odorless, non-toxic material that does not release harmful substances. It has good hygienic performance and is widely used in food processing, pharmaceuticals, and medical equipment, and meets hygienic standards and regulations.

Long Life And Low Maintenance Cost

316 stainless steel coil has a long life and low maintenance cost, due to its excellent corrosion resistance and mechanical properties, it reduces the frequency of parts replacement and maintenance and reduces the overall cost of use.

What Is the Difference between SUS304 and SUS316?

SUS304 and SUS316 are two common stainless steel materials, they are both 300-series stainless steel coils, but in some respects, they are slightly different:

In terms of chemical composition, SUS304 is an 18-8 type of stainless steel containing about 18% chromium and 8% nickel and also contains about 0.08% carbon and a small amount of silicon, manganese, and other elements. And SUS316 is a type 18-10-2 stainless steel that contains about 2% molybdenum in addition to about 18% chromium and 10% nickel. The addition of molybdenum improves the corrosion resistance of SUS316 in acidic and chloride environments.

In terms of corrosion resistance, SUS316 has better corrosion resistance and is more resistant to corrosion by various chemical media than SUS304, including acids, alkalis, and salts. Therefore, SUS316 is often used in occasions requiring high corrosion resistance such as marine environment, chemical industry, and food processing.

In the applicable temperature range, both SUS304 and SUS316 have good high-temperature performance, but the high-temperature resistance of SUS316 is slightly better than that of SUS304. SUS316 can maintain structural stability and strength at higher temperatures, so it is more common in high-temperature environments.

In daily life, if you observe, you will find that 316 stainless steel exists widely in life. The cost of 316 stainless steel is higher than that of 304 stainless steel. It is the material with the highest safety index in the food range, and its comprehensive performance is also better than that of 304 stainless steel.

316 Stainless Steel Coil Application

Due to its excellent performance, 316 stainless steel coils are widely used in various fields and applications, mainly in medical, food, machinery, petroleum, food industry, surgical equipment, solenoid valves, and other fields. Here are some of the applications we recommend for 316 stainless steel coils:

Chemical and petroleum industry: 316 stainless steel coils play an important role in the chemical and petroleum industry. They are used to manufacture chemical equipment, storage tanks, pipes, valves, etc., and can maintain good conditions under corrosive media, high temperature, and high-pressure conditions. It is widely used in acid and alkali treatment, petroleum processing, oil refining, and other fields.

Food processing and medical equipment: 316 stainless steel coils meet hygienic standards and are widely used in industries such as food processing, pharmaceuticals, and medical equipment. It can be used in the manufacture of food processing equipment, surgical instruments, medical instruments, etc. It has the characteristics of corrosion resistance and easy cleaning to ensure hygiene and food safety.

Shipbuilding and marine engineering: 316 stainless steel coils play an important role in shipbuilding and marine engineering because of their excellent seawater corrosion resistance. It is used to manufacture hulls, decks, ship accessories, offshore platforms, etc. It can resist seawater erosion and corrosion, and ensure the reliability and durability of ship structures.

High-temperature equipment: 316 stainless steel coils have good high-temperature resistance and can maintain structural stability and strength in high-temperature environments. It is used in the manufacture of furnaces, heating elements, heat exchangers and high-temperature piping, etc., and is suitable for applications such as high-temperature furnaces, burners, and heat treatment equipment.

Construction and decoration: 316 stainless steel coils are often used in the field of construction and decoration because of their exquisite appearance and smooth surface. For example, it is used to manufacture doors and windows, handrails, columns, decorative panels, etc., and is widely used in indoor and outdoor decoration of residential, commercial, and public buildings.

The above are just some common application scenarios of 316 stainless steel coils that we recommend. The excellent performance of 316 stainless steel coils makes it promising in many fields. If you have related needs, please feel free to contact us, and we will provide you with more Professional solutions for you to choose from.

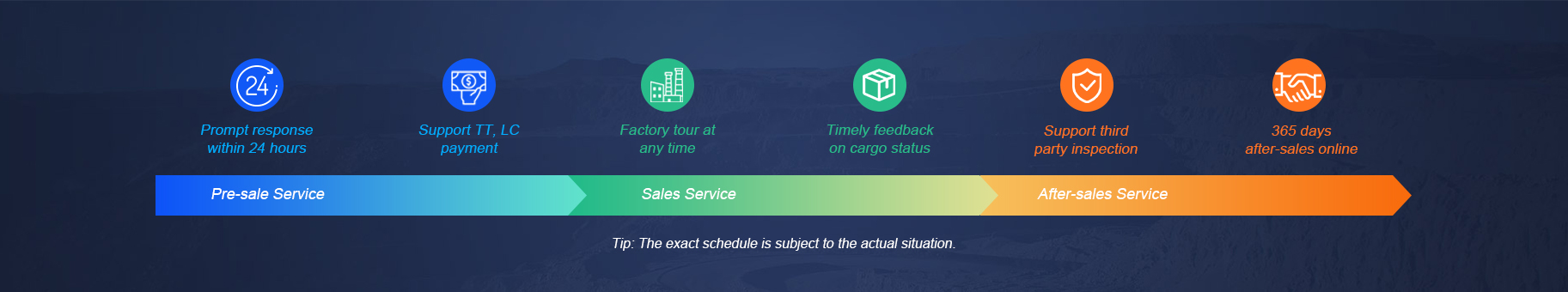

Reasons to Choose AnGang

The AnGang Steel Group is a professional supply chain enterprise, mainly engaged in steel plate, coil, profile, and outdoor landscape design and processing. After 15 years of development, it has become a leading international steel supply chain company in the Central Plains. Relying on many iron and steel enterprises such as Angang Steel, we have a wide variety of products, including shipbuilding plates, pressure vessel plates, bridge decks, etc. We also provide pipes, bars, engineering design and manufacturing, and comprehensive stainless steel solution services. Cooperating with more than 600 companies around the world, the annual export capacity exceeds 80,000 metric tons. Choose AnGang Steel Group, you choose a professional and reliable steel supply chain partner!