Product Specification and Characteristics

- It contains Mo element, so it has excellent corrosion resistance, atmospheric corrosion resistance, and high temperature resistance, and can be used under harsh conditions.

- High strength and hardness: After cold rolling or cold drawing processing, the material has high strength and hardness, allowing it to endure more weight and pressure in some circumstances.

- Solderability: This property makes a material simple to handle, weld, and connect to other stainless steel pipes.

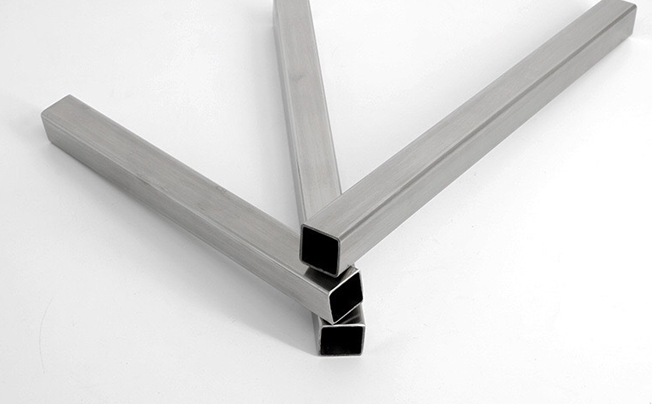

- It’s beautiful: Thanks to its distinctive shape and metal texture, it offers wonderful, contemporary, and long-lasting design qualities. The surface is bright and flat, appropriate for indoor and outdoor architectural decorating, furniture construction, etc.

- Safe and hygienic: non-toxic, odorless, won’t contaminate liquid being transported, and complies with health standards.

| Item | 316L Stainless Steel Square Tube

|

|

| Standard | ASTM, DIN, GB, or customized size required by customers | |

| Material | C, Fe, Mo, Mn, Si, N, etc. | |

| Type | hot rolled and cold rolled | |

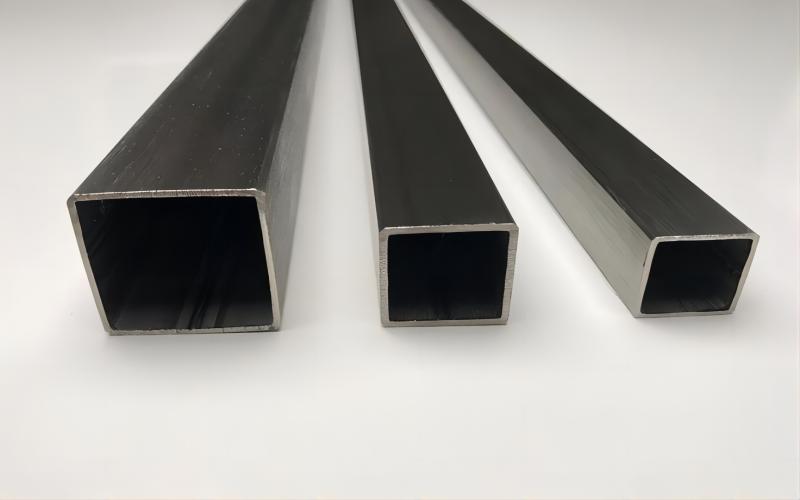

| Size | Wall Thickness | 0.5~6mm |

| Outer Diameter | 3mm~300mm | |

What is the difference between 316 and 316L?

1. Chemical composition: 316L stainless steel has a lower carbon content than 316 stainless steelsquaretube, but a higher molybdenum content than 316.

2. Corrosion resistance: The latter is a little stronger in corrosion resistance.

3. Strength: 316 has high carbon content, so the mechanical properties are stronger and the tensile strength is greater.

4. High temperature resistance: The carbide precipitation resistance of 316L stainless steel is better than that of 316 stainless steel, which can be used at high temperature and can continue to withstand the environment of 800~1575 degrees. But 316 cannot.

5. Welding: 316 stainless steel has good weldability, and general standard welding methods can weld it. Its welding section needs to be annealed after welding to improve its corrosion resistance. However, if 316L stainless steel is used, post-weld annealing is not required.

6. Production cost: 316L stainless steel square tubehas low carbon content and is easy to weld, so its price is more expensive than 316 stainless steel pipe, but the difference is not much.

7. Specific application: From the manufacturer’s point of view, stainless steel factories are more willing to produce 316L steel, so the actual circulation on the market is basically low-carbon 316L stainless steel, generally 316 stainless steel is rarely sold, unless there are special requirements.

8. Scope of use: From the perspective of material cost, the use of 316L steel pipe is about 1.5 times that of 306 stainless steel pipe, so the amount of 316L should be customized.

Applications of 316L Stainless Steel Square Tube

1. Building decoration: The material is a popular choice for both indoor and outdoor architectural decoration because of its brilliant, smooth surface and outstanding corrosion resistance. for instance, wall decorations, chairs, guardrails, and doorknobs.

2. Food and medical fields: as it is non-toxic, odorless, and won’t cause pollution, it is widely used in the food processing sector and the medical profession. It also complies with health standards and requirements for global sustainable development. such as coffee cups, surgical instruments, medicinal supplies, etc.

3. Chemical and petroleum industry: Because of its superior bending strength and resistance to high pressures and high temperatures, it can be used to transport a variety of chemical media and petroleum products, including storage tanks and pipeline transportation.

4. Marine engineering: 316L stainless steel square tubehas excellent seawater corrosion resistance, so it is widely used in the field of marine engineering, used in the manufacture of marine pipelines, ship equipment, seawater treatment equipment, etc.

5. Heat exchangers and cooling systems: It can withstand high temperatures and corrosive media, so they are widely used in heat exchangers and cooling systems to manufacture heat exchanger tubes, condensers, cooling towers, etc.

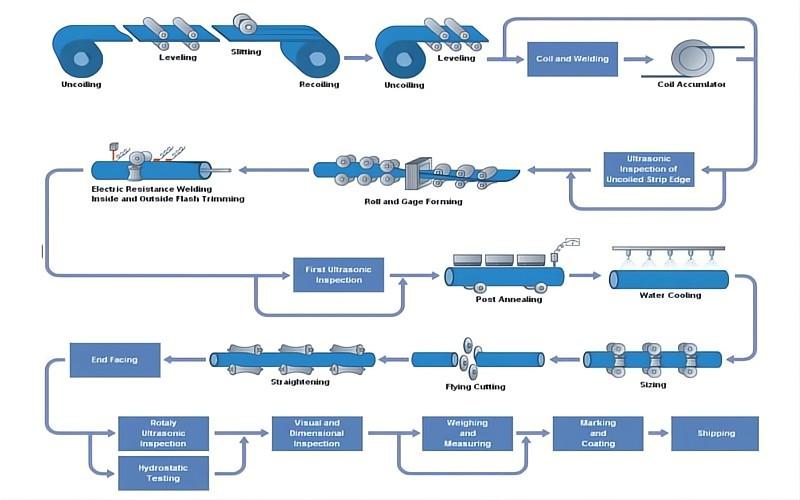

Manufacturing Process

Material preparation: 316L stainless steel square tube is selected as raw material and cut into corresponding sizes according to design requirements.

Bending forming: The plate is bent to make it square or rectangular in shape. It can be bent according to actual needs by cold bending, hot bending or mechanical bending.

Welding: Bend-formed stainless steel plates are welded to join adjacent edges together. Common welding methods are TIG (tungsten argon arc welding), MIG (metal inert gas shielded welding), resistance welding, etc.

Polishing and finishing: Welded joints are polished and surface treated to make them flat, smooth, and improve their aesthetics and corrosion resistance.

Dimensional and quality inspection: Dimensional measurement and quality inspection of the manufactured square tube to ensure that it meets the design requirements and relevant standards.

Packing and shipping: Qualified square tubes are packed to protect their surfaces from damage, and delivered or stored at the factory.

Quality Control

Quality control is an important process to ensure that 316L stainless steel square tube products meet the expected quality standards. Here are some common quality control measures and methods:

1. Check the chemical composition, appearance quality, performance, etc. of the purchased raw materials to ensure compliance with relevant standards and specifications.

2. Use appropriate measuring tools and equipment to measure the length, outer diameter, wall thickness, etc. of the manufactured pipe to ensure compliance with design requirements and relevant standards.

3. Check the surface of the pipe through visual inspection, touch and visual inspection, including appearance, flatness, surface finish, etc., to ensure that its surface is free of obvious defects, imperfections or corrosion.

4. Tensile test and other strength and hardness tests are carried out on the pipe to evaluate the mechanical properties and pressure resistance of the product.

5. Salt spray test, chemical corrosion test, etc. of the pipe to verify its corrosion resistance.

6. Quality inspection of welded joints through visual inspection, ultrasonic testing, radiographic inspection and other methods, including weld appearance, weld strength, etc.

7. Carry out product certification and standard compliance assessment as needed. This can include ISO 9001 Quality Management System Certification, CE Certification, etc., to ensure that products comply with relevant quality and safety standards.

Market Competition and Prospect

Numerous domestic manufacturing firms have continuously gained their market share both domestically and internationally as the demand for steel has risen. Additionally, they have traveled abroad to form strategic alliances with various reputable global firms. Their goods are shipped to a number of countries and areas, including the US, South Korea, Australia, South Africa, and Southeast Asia.

316L stainless steel square tube faces fierce competition in the market, and the quality, performance and price of the product are the primary considerations for users.

At the moment, stainless steel is becoming more and more well-known as a material. Manufacturers of stainless steel square tubes are prospering both domestically and abroad, contributing to the expansion of both regional and global economies.

The AnGang Steel Group is a supply chain business that combines the design and manufacture of panels, pipes, and profiles with outdoor landscaping and the sales of small goods internationally. Since its founding in 2008, we have been committed to realizing the company’s mission of becoming the most competitive supply chain group in the world by providing exceptional, reliable, and cutting-edge services. After putting up many years of effort, AnGang Steel Group has emerged as the Central Plains’ most skilled steel supply chain international firm.