4 Way Ball Valves Stainless Steel

What is a four-way ball valve stainless steel?

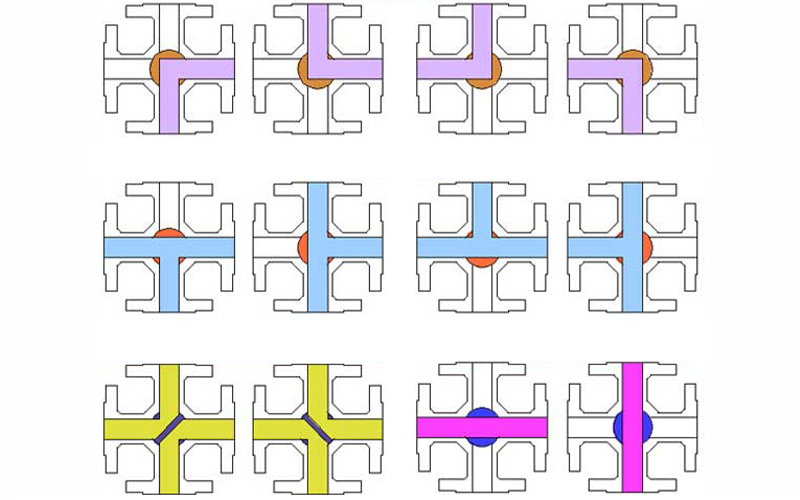

Four-way ball valve stainless steel refers to a pipe connection element made of stainless steel. The shape of the four-way ball valve stainless steel is a sphere with four outlets, which can realize the diversion or flow adjustment of multi-pipeline fluids. It is widely used in petroleum, chemical, metallurgy and other occasions that need to direct fluids to multiple directions or control multiple flows.

|

Product Name

|

4 Way Ball Valves Stainless Steel

|

|

Standard or Nonstandard

|

Standard

|

|

Pressure

|

Medium Pressure

|

|

Operation

|

Manual

|

|

Material

|

Stainlesss Steel

|

|

Media

|

Water, Oil, Gas

|

|

Temperature

|

Normal Temperature

|

|

Size

|

1/2″-4″

|

|

Place of Origin

|

Tianjin, China

|

|

Connection

|

Threaded

|

|

Structure

|

Ball

|

Four-way ball valve stainless steel pipe fittings features

Four-way ball valve stainless steel pipe fittings have the characteristics of corrosion resistance, high temperature and high pressure, so that it is widely used in all walks of life.

1, corrosion resistance: made of stainless steel four-way ball valve fittings, with high corrosion resistance, can resist a variety of chemical substances corrosion, widely used in petroleum, chemical and other industries.

2, high temperature and high pressure performance: stainless steel four-way ball valve fittings, with high temperature resistance and pressure resistance, suitable for high temperature environment.

3, wear resistance: four-way ball valve fittings made of stainless steel have good wear resistance, can resist the wear of particulate matter, suitable for sewage treatment and other industries.

4, health performance: made of stainless steel four-way ball valve fittings have good health performance, suitable for easy to clean and disinfect, need to meet the health standards of the food and pharmaceutical industry.

5, sealing performance: made of stainless steel four-way ball valve fittings have good sealing, can effectively prevent leakage.

What are the implementation standards and materials for stainless steel pipe fittings for four-way ball valves?

Four-way ball valve stainless steel pipe fitting implementation standards:

ASME:ASME B16.9,ASME B16.11,etc

EN:EN 10253-3,EN 10253-4,etc

DIN:DIN 2605,DIN 2615,etc

JIS:JIS B2311,JIS B2312,etc

GB:GB/T 12459,GB/T 13401,etc

Four-way ball valve stainless steel pipe fitting material:

ASTM:F304、F316、F321、etc

EN: EN 1.4301、EN 1.4401、etc

JIS:SUS304、SUS316、etc

GB: 0Cr18Ni9、0Cr17Ni12Mo2、etc

Four-way ball valve stainless steel in various industries

Four-way ball valve stainless steel pipe fittings are widely used in various industries because of their corrosion resistance, high strength and other properties.

1, oil and gas industry: commonly used in oil refineries, natural gas processing plants and oil well pipeline systems in the import and export pipelines, diversion systems and control systems.

2, chemical industry: usually installed in chemical reactors, storage tanks and other pipeline systems and equipment connections, used to control the flow direction, adjust the flow rate

3, pharmaceutical industry: usually used for raw material import and export, reactor import and export, transportation pipeline, etc.

4, food and beverage industry: often used in food processing pipeline systems, used to control fluid flow and other processes.

5, sewage treatment industry: often used in sewage treatment and drainage system inlet and outlet, mixing chamber, sedimentation tank and other locations, control and regulate the treatment and flow of wastewater.

Four-way ball valve stainless steel pipe fittings manufacturing process

The manufacturing process of stainless steel pipe fittings for four-way ball valves includes the following steps: material selection – casting or forging – sheet metal processing – forming – welding – processing and assembly – sealing ring installation – surface treatment – inspection and quality control – packaging and labeling – leaving the factory

What should be paid attention to during the use of four-way ball valve stainless steel pipe fittings?

When using four-way ball valve stainless steel pipe fittings, the following points need to be paid attention to:

1, Installation location: Before installing the four-way ball valve stainless steel pipe fittings, it is necessary to measure and plan the installation location, select a suitable location for installation, and ensure that the installation location is convenient for later operation and maintenance.

2, Pressure and temperature: Know the pressure and temperature that the four-way ball valve fittings can withstand before use. Excessive pressure and temperature may cause rupture or damage to the fittings.

3, Sealing: Before installing the stainless steel pipe fittings of the four-way ball valve, check whether the seal of the ball valve is intact, and apply a proper amount of sealant.

4, Operation method: Follow the correct operation method to prevent damage to the pipe fittings due to excessive force during operation.

5, Regular inspection and maintenance: Carry out regular inspection and maintenance on the ball valve fittings to ensure the normal operation of the ball valve fittings, and repair or replace them in time if any damage or leakage is found.

What are the differences between stainless steel four-way pipe fittings and four-way ball valve stainless steel pipe fittings?

The application scope and advantages of stainless steel four-way pipe fittings and four-way ball valve stainless steel pipe fittings are different, and the appropriate pipe fittings should be selected according to the use scenario.

1, Different performance: stainless steel four-way pipe fittings are used for diverting or confluence of fluids in multiple directions in the pipeline system; Four-way ball valve stainless steel fittings for the control of fluid flow rates in multiple directions.

2, the difference in structure: stainless steel four-way pipe fittings are straight-through structure, the appearance is “T” shape; Four-way ball valve Stainless steel pipe fittings are ball valve structure.

3, Different control capabilities: Because stainless steel four-way pipe fittings are straight-through structures, they do not have the ability to control and adjust the fluid; Because the four-way ball valve stainless steel pipe is a ball valve structure, it can accurately control and adjust the fluid.

4, Different modes of use: stainless steel four-way pipe fittings are usually used to connect pipes and are used with other pipe fittings; Four-way ball valve stainless steel fittings are controlled by rotating spheres.

5, Application scenario: stainless steel four-way pipe fitting is suitable for various pipe systems; Four-way ball valve stainless steel fittings for piping systems that require precise fluid control.