Stainless steel pipe is a hollow, long, round piece of steel that is widely utilized in petroleum, chemical, medical, food, light industrial, and other areas. It has a variety of uses in the national economy and is a significant product in the steel industry. The two most popular materials used to make this pipes are 201 and 304.

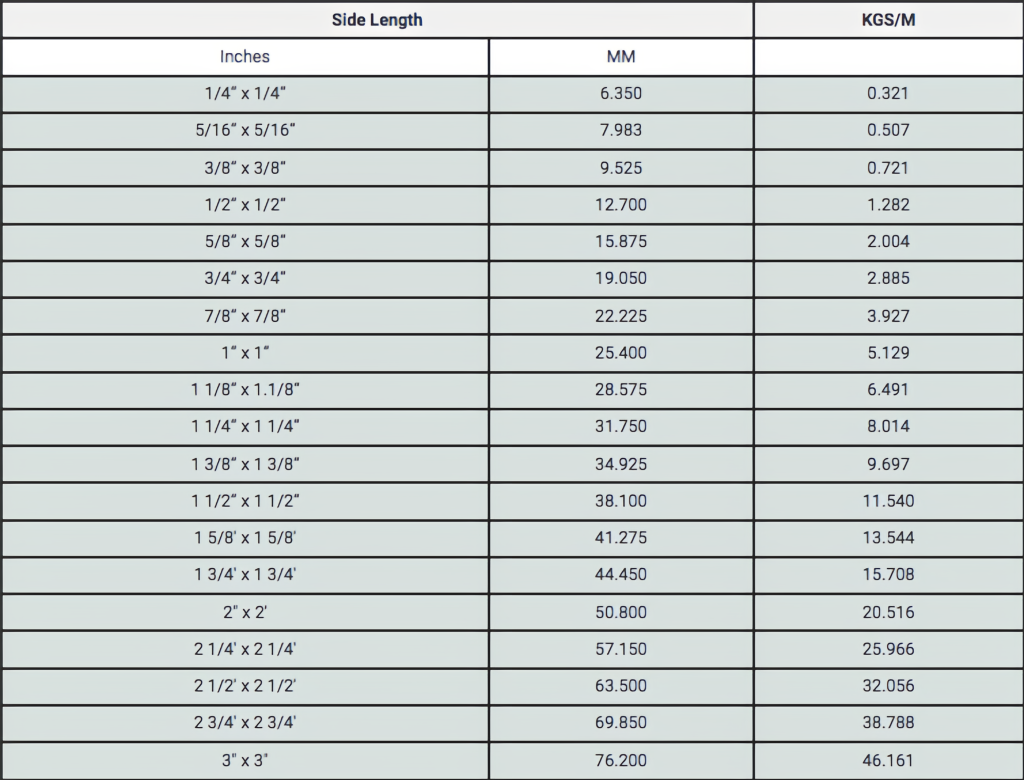

Product Specification Table

What is the difference between galvanized pipe and stainless steel pipe?

Material quality: The main component of stainless steel pipe is an alloy made of at least 10% chromium, which is not easy to rust at room temperature. Galvanized steel pipe is electroplated with a layer of zinc outside the steel pipe to protect the pipe from rust.

Connection method: The majority of connections are made by welding, although there are also clamp connections and welded flange connections. It is difficult to sleeve wire because stainless steel pipe has high strength. However, welding is typically not permitted on zinc steel pipes because it will erode the galvanized coating and induce electrochemical corrosion between the solder and the layer. Therefore, wire button flange connections, clamp connections, and wire button connections are typical.

Properties: Galvanized steel tends to be more ductile and manageable than stainless steel, but it is also less durable and more prone to corrosion. Galvanized steel is also less expensive than stainless steel in terms of price. Although it is easier to handle, it is not as strong as stainless steel. When the lifespan of a construction project is important, stainless steel is advised since it has a far longer service life than galvanized steel.

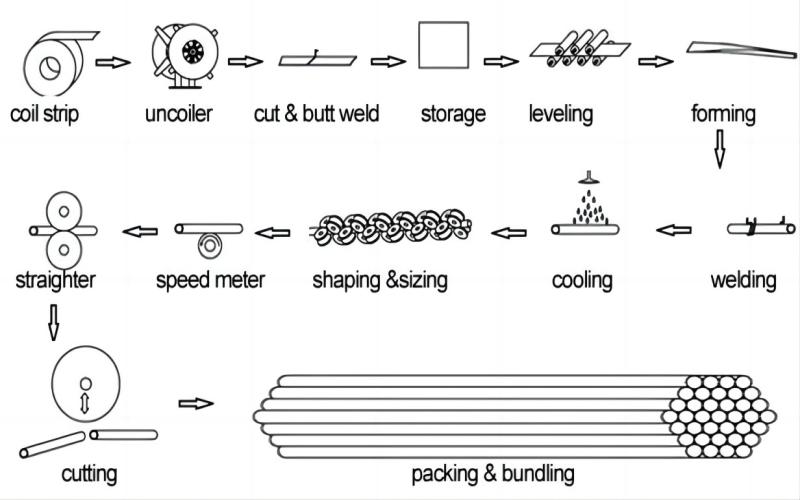

Stainless Steel Pipe Production Process

Decorative welded pipe: Raw materials – Slitting – Pipe fabrication via welding – End repair – Buffing – Printing inspection – Packaging – Shipping and storage.

Welded pipe industrial piping with pipe: Raw substance – Slitting – Pipe welding – Heat therapy – Pickling – Pickling – Hydraulic test – Straightening – Straightening – End trimming – Printing inspection – Presentation – Shipping and storage.

Types and Applications

1. Decorative pipes: Also known as stainless steel welded steel pipe, a welded pipe is a term that refers to steel or steel strip that has been curled and formed into a pipe by a unit or mold. The overall strength is lower than that of seamless steel pipe despite having a brighter or wire-drawn surface, a straightforward production process, high production efficiency, numerous variants, and fewer devices. The primary materials are 201 and 304, which are utilized primarily in decoration engineering.

2. Artifact pipes: Stainless steel product pipes are stainless steel pipes that have been specifically made to meet the needs of the customer, and they must adhere to stringent specifications for positive and negative characteristics, workmanship, surface brightness, and other factors. They must also meet bending and expansion requirements. The material is mostly utilized in bathrooms and homes, as well as in product piping, fluid pipe, etc.

3. Special-shaped pipes: These are separated into welded and seamless varieties, and the predominant materials are 304, 304L, and 316L. According to the section and overall shape, tubes may be separated into a variety of particular shapes. Depending on the use, tubes can also be split into categories such as construction, mechanical, and decorating.

4. Pipes with patterns: Typical embossing often features a gourd pattern, whereas European embossing features lucky clouds, money, and other patterns. Choose items with various patterns based on the needs of the procedure.

5. Colored pipes: The surface of the colored stainless steel tube is covered in a coating of color, creating a vibrant effect with a long lifespan. 201 and 304 are the two most often used materials, and the coloring procedure entails vacuum coating, water plating coloring, baking paint, copper plating, etc. widely used as screens, fences, stair handrails, courtyard gates, etc. in luxury hotels, clubs, and mansions.

6. Composite pipes: Including stainless steel composite pipe and carbon steel composite pipe which are rare now.

7. Industrial pipes: Made of stainless steel plate, industrial pipes come in both welded and seamless varieties. With excellent seismic performance and impact resistance, they are primarily used in engineering structures such as bridges and pipelines of all shapes and sizes.

Is stainless steel pipe better than PVC?

Many people initially consider PVC pipes when they think about drinking water. The use of stainless steel pipes is very common internationally. The following are the causes: First of all, stainless steel is stable and resistant to temperature changes, therefore it won’t produce any hazardous compounds at high or low temperatures. Second, it has higher strength and stronger corrosion resistance than PVC. As a result, it has a longer service life and the issue of burst water pipes is no longer a concern. Once more, it has a low leakage rate and is effective at safeguarding water supplies.

However, PVC water pipes are used more in China, because the price is a little more affordable than stainless steel pipes. Therefore, when choosing decoration materials, you can choose a more suitable one according to your own preferences and your own needs.

Why should I choose stainless steel pipes?

Consumers should think about stainless steel pipes whether they have commercial or domestic purposes. They are not only very long-lasting and resistant to corrosion, but they also require less maintenance than other kinds of pipes. Stainless steel tubes are unrivaled in their durability and capacity to withstand high temperatures and challenging environmental conditions. They are also quite adaptable and may be utilized in many different industries, including food and beverage processing and construction. Therefore, the pipes are an excellent option for customers who want pipes that will endure the test of time, be simple to maintain and function flawlessly with other equipment.

Market Competition and Prospect

Exports of stainless steel make up a significant portion of China’s export sector, which is a major factor in the country’s economic expansion.

The construction of infrastructure is becoming more and more necessary as the world becomes more urbanized. The construction, automotive, and industrial sectors, among others, are among those with the highest demand in the upcoming years. Currently, stainless steel is gaining popularity as a material. Manufacturing of stainless steel pipes is flourishing both domestically and internationally, which helps the local and worldwide economies grow. Enterprises should concentrate on bolstering their management and quality control in order to improve the competitiveness of stainless steel products.